China built a 10-story building in 29 hours — Here’s How!

What if the skyline of a city could change overnight? In China, that question has become a stunning reality. In just 28 hours and 45 minutes, the BROAD Group erected a 10-story residential tower using modular steel construction, forever altering the global conversation around how we build cities. While it may sound like science fiction, it’s real — and it’s only the beginning.

Who Is the BROAD Group?

Founded in 1988 and headquartered in Changsha, BROAD Group is best known for its energy-efficient air conditioning systems. But since 2009, the company has also been a quiet revolutionary in the construction sector, investing in modular, prefabricated, factory-built steel structures.

Their newest achievement: a fully functional high-rise completed faster than most single-family homes are framed.

The Science Behind Speed

The secret lies in modular construction — a process where steel modules (or “Living Building Units”) are built off-site in a factory-controlled environment. These modules are then transported to the site and stacked with the precision of Lego bricks.

Each unit includes:

-

Pre-installed wiring and plumbing

-

Built-in insulation and ventilation systems

-

Fireproof and earthquake-resistant walls

Instead of building brick by brick, floor by floor, BROAD constructs entire rooms and simply assembles them on location.

The Timeline: 28 Hours, 45 Minutes

The entire structure — dubbed the Living Building — was assembled in just over a day.

Breakdown of the process:

-

Pre-construction preparation: 3 months of module manufacturing

-

Transportation to site: 12 hours prior to build

-

On-site assembly: 28 hours, 45 minutes

-

Operational testing and interior finishing: under 72 hours

It’s not just the fastest build — it’s one of the most efficient.

Why It Works: The Engineering Masterstroke

BROAD uses high-strength stainless steel frames and a proprietary joining system that requires no welding. Instead, modules are bolted together and locked into place by mechanical seals.

This means the structure is strong enough to resist Level 9 earthquakes and hurricane-force winds.

Other engineering breakthroughs include:

-

Air filtration systems to block PM2.5 pollutants

-

Energy recovery ventilation (ERV)

-

Smart thermostats in every unit

-

Passive solar design

Cost and Efficiency

While exact numbers vary based on configuration, BROAD claims:

-

Cost per square meter is 30–50% less than conventional builds

-

Construction time reduced by over 90%

-

Labor requirements reduced by up to 80%

-

Construction waste reduced by over 90%

A Safer, Cleaner Construction Site

Unlike traditional construction, which is chaotic and dangerous, modular builds are:

-

Nearly dust- and debris-free

-

Far quieter, with no heavy jackhammer noise

-

Safer, with significantly fewer worker injuries

The result is a construction site that feels more like a logistical operation than a messy build zone.

Sustainability at Scale

The Living Building is not just fast — it’s green.

Each module is:

-

100% recyclable

-

Designed to minimize thermal bridging

-

Optimized for natural lighting and airflow

BROAD also powers its factories with renewable energy, lowering the carbon footprint of each building.

Digital Twin Technology and AI Planning

BROAD’s flawless execution relied on digital twin simulation and AI-assisted scheduling. Before assembly, the entire project was simulated in 3D to optimize:

-

Structural integrity

-

Assembly sequence

-

Equipment coordination

The result: zero downtime and a perfectly choreographed build.

Global Implications for Disaster Relief

Beyond housing, this system could be life-saving in emergencies:

-

Post-earthquake shelters

-

Field hospitals

-

Housing for climate refugees

Speed and scalability make it a game-changer for humanitarian crises.

Challenges and Skepticism

Not everyone is convinced.

-

Some architects argue the buildings look too uniform.

-

Local regulations can slow modular adoption.

-

Labor unions raise concerns over job losses.

Still, with housing shortages and urban migration rising, modular construction may become impossible to ignore.

The Future: High-Rises in Days, Not Decades

BROAD has already built a 57-story tower in just 19 days, proving the technology works at scale. Their long-term vision includes:

-

Skyscrapers over 200 stories tall

-

Carbon-neutral cities assembled in under a month

-

Affordable housing solutions for the global population boom

Conclusion

28 hours and 45 minutes is more than just a record — it’s a revolution. BROAD Group’s 10-story marvel shows us that cities don’t have to grow slowly. With the right technology, the future can rise overnight.

And if the rest of the world follows China’s lead, the skylines of tomorrow may be shaped not by cranes, but by logistics trucks delivering ready-to-stack dreams.

News in the same category

Eunice Foote: The Forgotten Scientist Who Predicted Climate Change in 1856

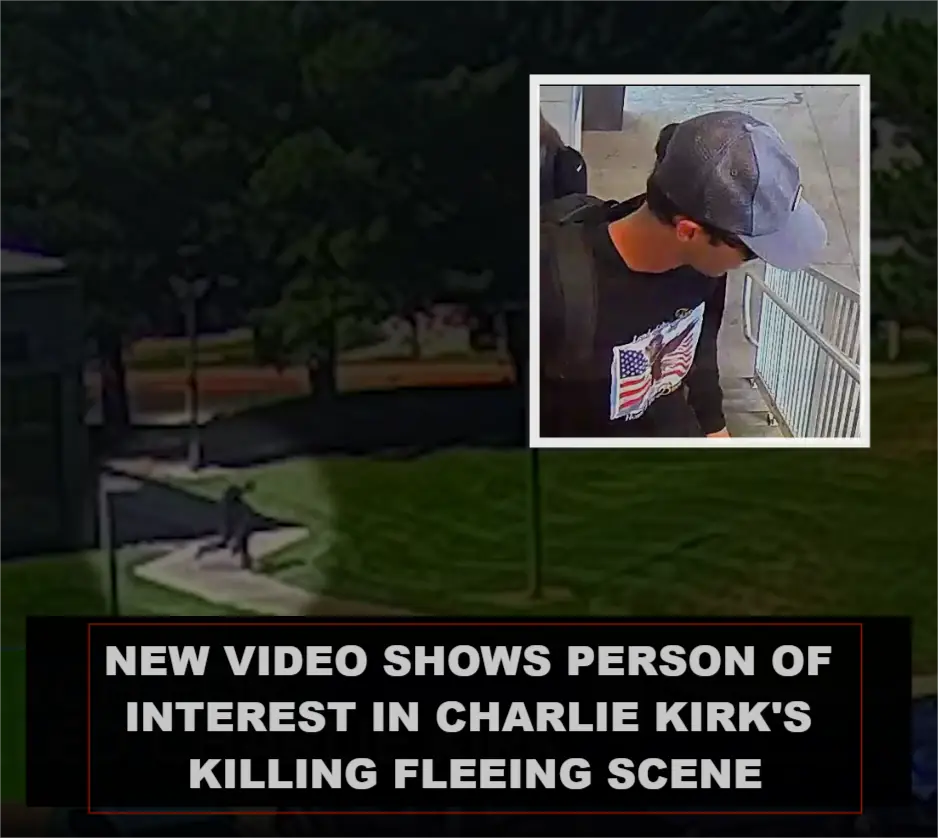

Charlie Kirk shooting: Officials release video, plead for help in tracking down person of interest

California's Clean Air Vehicle Decal Program to End This Month

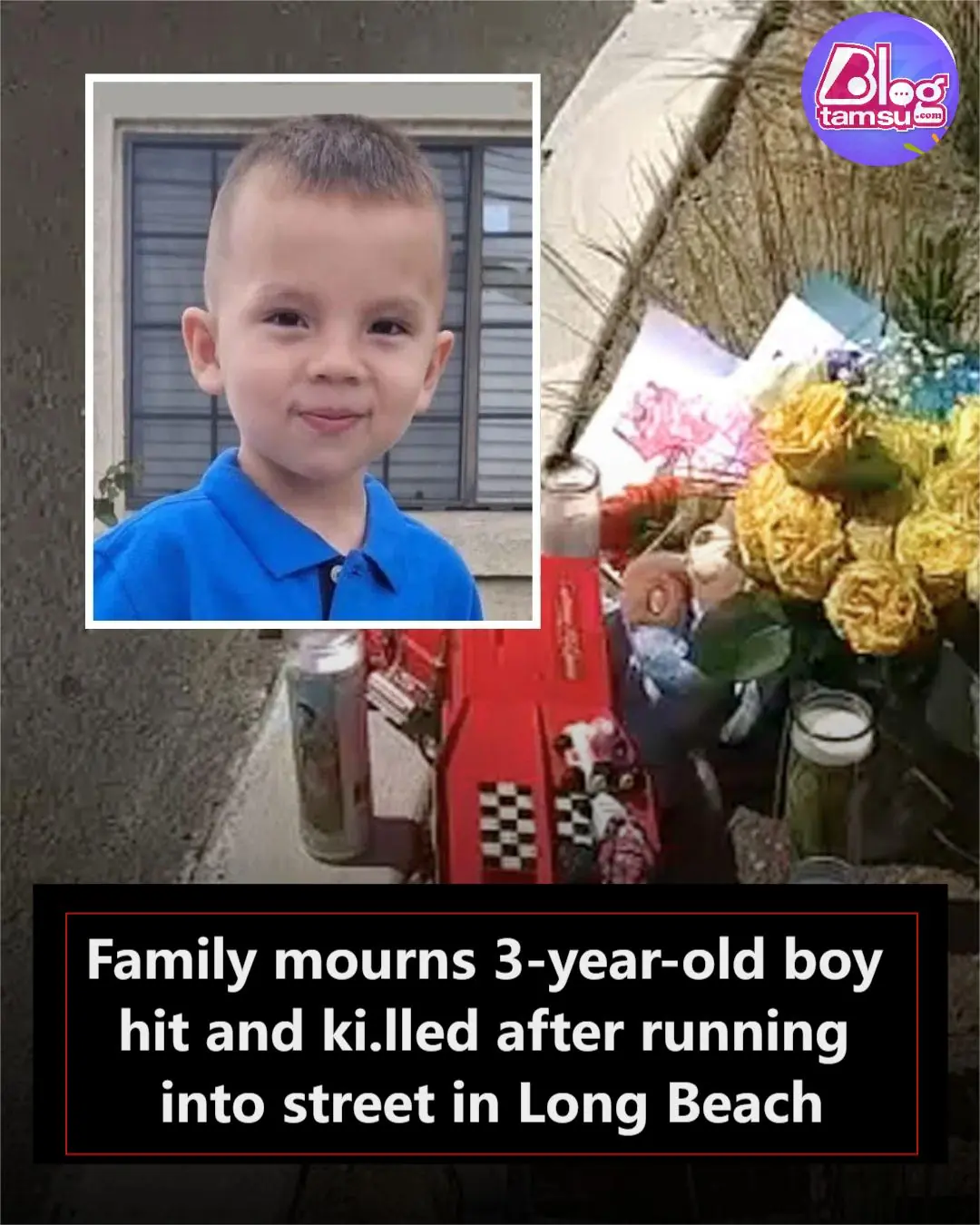

Family mourns 3-year-old boy hit and killed after running into street in Long Beach

Did Charlie Kirk start asking the wrong questions?

Terror on Boeing 737 as plane explosion forces pilots to make ‘hard landing’: ‘Unsettling’

Emma Heming reveals Bruce Willis is living in a second home as dementia battle progresses: ‘Hardest decision’

Professor Cancels Class After Taylor Swift and Travis Kelce Engagement News Goes Viral

Bubbles at 42: From Pop Icon to Sanctuary Resident, a Chimpanzee’s Quiet Legacy

France’s Carmat Artificial Heart: A Game-Changer in Transplant Medicine

Charlie Kirk’s final words before being assassinated

Russia Launches Free mRNA Cancer Trials — A New Hope for Treatment

Russia’s $100 Billion Pipeline Shift: From Europe to China

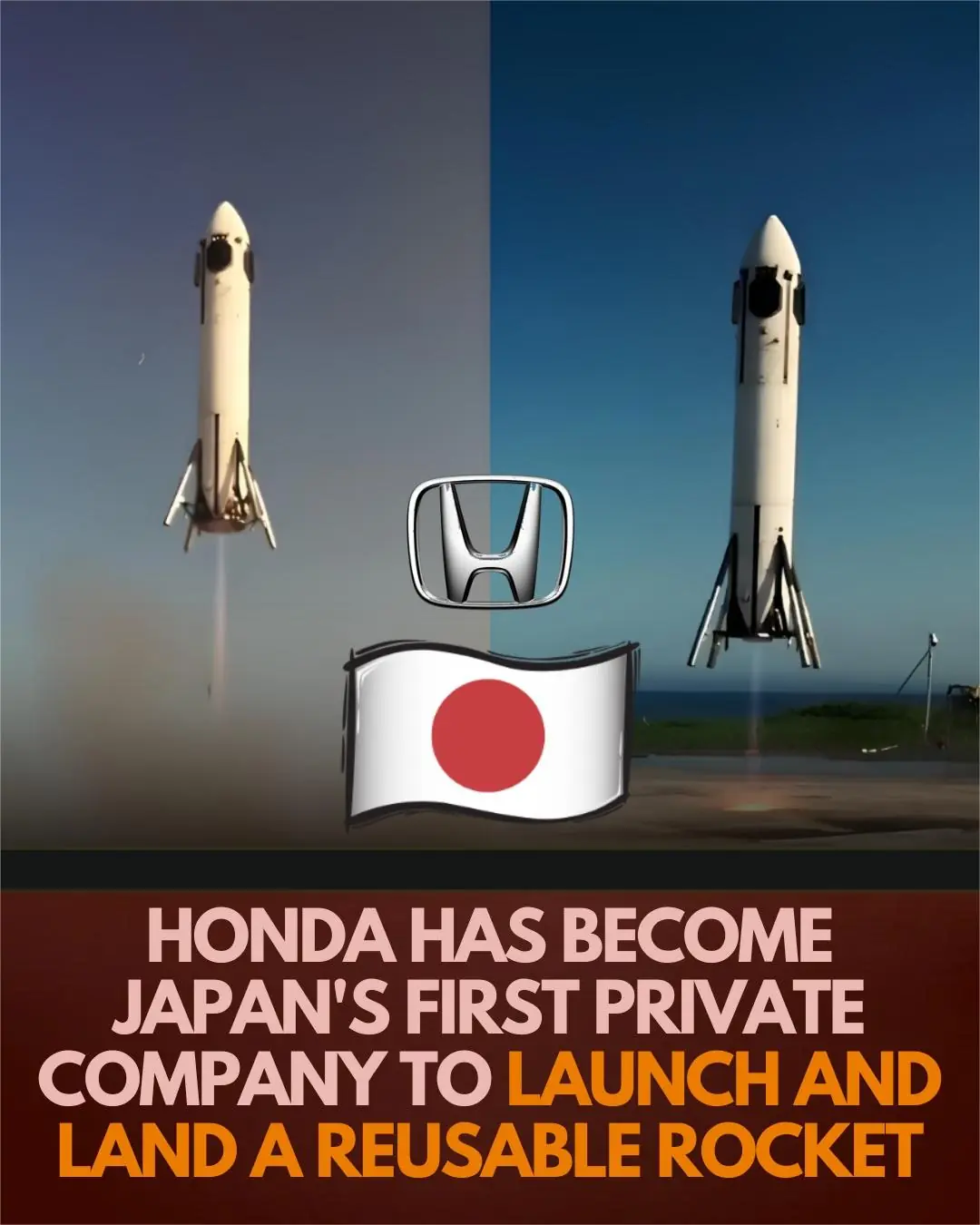

Honda’s Reusable Rocket Milestone: What We Know So Far

Iceland: The Rare Nation Without Mosquitoes

Dubai Pushes Ahead with Self-Driving Electric Trucks to Transform Logistics

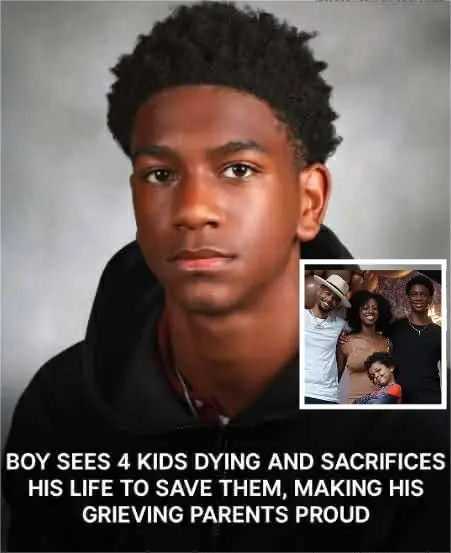

Tragedy as teen drowns rescuing four children – his family reveals his legacy

News Post

Mix Hibiscus Flower with Bay Leaves and Cinnamon

Homemade Onion Hair Oil for Stronger, Healthier Hair

Erika Kirk delivers emotional remarks after killing of husband Charlie Kirk

The Hidden Meaning of the “M” on Your Palm 🤲✨

10 Innocent-Looking Household Items That Can Cause Cancer (Backed by Science)

Eunice Foote: The Forgotten Scientist Who Predicted Climate Change in 1856

Research Suggests Your Body Knows When Death Is Near — And It Begins With the Nose

The drink that eliminates diabetes, fatty liver, poor circulation, and cancer without the need for expensive pills 👇

The drink that eliminates diabetes, fatty liver, poor circulation, and cancer without the need for expensive pills

Charlie Kirk shooting: Officials release video, plead for help in tracking down person of interest

California's Clean Air Vehicle Decal Program to End This Month

Family mourns 3-year-old boy hit and killed after running into street in Long Beach

Did Charlie Kirk start asking the wrong questions?

How to Identify Benign and Malignant Lymph Nodes

8 Surprisingly Easy Ways to Prevent Cavities

Take a spoonful of olive oil with lemon every day on an empty stomach.

Unlock the Secret to Glossy, Vibrant Hair with Cloves and One Simple Trick!

Nature’s Ultimate Detox Secret: Cucumber, Lemon, Celery, and Turmeric for a Healthier You!

Unlock Radiant Skin: The Colgate and Lemon Glow Secret You NEED to Know!